How To Fix Acer Desktop Boot Loop Issue: The Ultimate Computer REpair Singapore

The Acer Desktop boot loop issue can be a frustrating problem for users, causing their computers to restart continuously without reaching the operating system. This

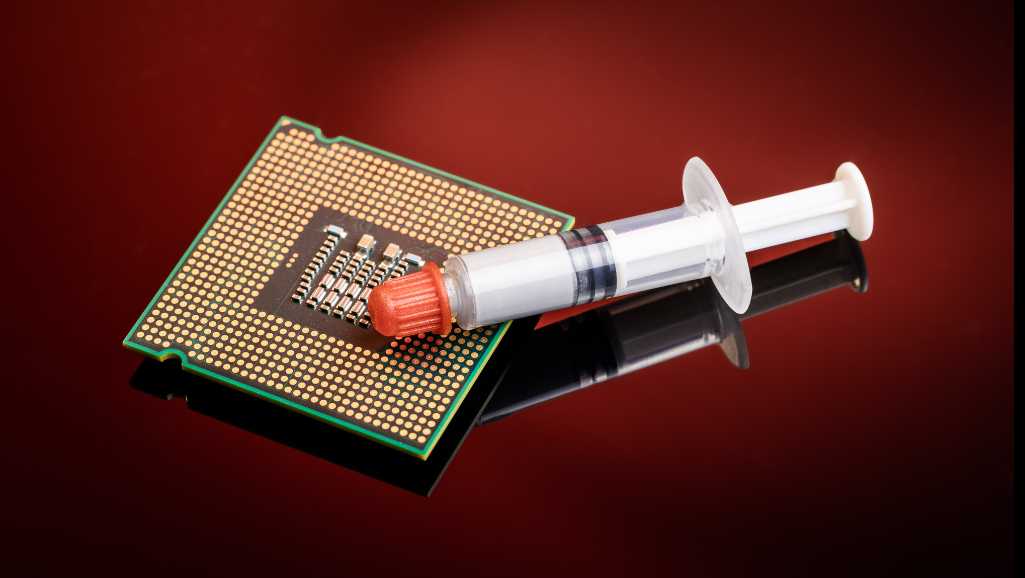

When repairing a computer, whether it is a desktop PC, laptop, games console or mobile device, applying new thermal paste is by far the most critical step. Thermal paste transfers heat away from delicate electronics like the CPU, GPU and chipset, preventing overheating damage. While often overlooked by amateur repair technicians, properly applying fresh high-quality thermal paste can make the difference between a successful, long-lasting computer repair versus continued crashes and malfunctions.

In this comprehensive guide, we will cover everything you need to know as a computer repair technician about working with thermal paste.

Table of content:

Also referred to as thermal compound, thermal interface material (TIM), thermal grease or heat paste, thermal paste is a thermally conductive adhesive paste used to efficiently conduct heat from computer components to cooling systems.

This paste fills microscopic air pockets between hot computer parts like the processor, graphics chip(s), RAM and voltage regulation modules (VRMs) on the motherboard and their accompanying solid metal heatsinks and liquid cooling blocks. By filling minuscule gaps, it allows for direct heat transfer away from the electronics.

Thermal paste is an absolute necessity when repairing computers to prevent critical components from overheating.

During the manufacturing process of computer parts, the processors, GPUs and other chips are mated with heat spreaders to dissipate heat. However, the machined surfaces contain tiny microscopic valleys and grooves even after advanced polishing techniques.

When joining the uneven surfaces of silicon dies and heatspreaders, these microscopic air gaps act as insulation that traps heat against the sensitive electronics. Excessive accumulated heat causes computer crashes, lockups, unexpected reboots and sharply reduces the lifespan of your clients’ repaired devices.

By using thermally-conductive paste to fill in these minuscule voids, heat can efficiently transfer away from delicate computer components to keep temperatures lower for stable performance. Leaving old degraded paste or failing to apply a new layer is asking for future computer problems!

To understand why thermal paste is so important for computer repairs, you need to comprehend the science of how thermal compounds function.

All thermal pastes contain thermally conductive metal particles like aluminum, silver or zinc suspended in a thick silicone polymer grease. Some pastes utilize ceramic powders or carbon compounds instead.

When a thin layer of this dense paste is applied between the hot surfaces of computer chips and their heatsinks/cooling blocks, the thermally conductive particles create a bridge to transfer heat energy. This allows absorbed heat to rapidly dissipate away from sensitive electronics.

The paste particles fill microscopic grooves and valleys in the hardware, displacing inefficient air pockets trapped between them. Air is a poor conductor of heat – the paste replaces air gaps with a surface that conduits heat efficiently to the cooler. Removing air barriers allows for full, unimpeded contact for heat to channel away.

Quality thermal paste thereby drops chip temperatures substantially compared to relying solely on the metal-to-metal contact. Without paste, the microscopic air gaps caused by surface imperfections severely throttle thermal transfer.

So in summary, thermal paste works by filling microscopic valleys and channels to permit unobstructed heat conduction between computer chips and cooling systems.

You may be wondering why existing thermal paste needs to be cleaned off and replaced if manufacturers already apply a layer from the factory.

The reason is that thermal paste performance severely degrades over months and years of heat cycling and mechanical shocks. As computers heat up and cool down repeatedly, thermal paste slowly loses moisture content and contracts. What begins as smooth, pliable paste sets into concrete-like rigid chunks with weaker thermal transfer.

The bonding agents and filler used in pastes also slowly migrate over time. Separating from the thermally conductive materials, gaps form inside the paste that interrupt heat dissipation. Hardened paste simply lacks the metal content to effectively move heat.

Factors like jostling of desktop PCs during transport or the bending of laptops accelerates the drying out process. The hardened paste cracks, losing the vital contact. Once a system surpasses 3 years old, replacing factory thermal paste with fresh paste is highly advised for optimal cooling, unless liquid metal was used.

With so many thermal paste products available, choosing a suitable TIM can feel overwhelming. However, only several key characteristics really matter for an effective thermal interface material. Consider the following when selecting a thermal paste:

This spec determines how readily heat moves through the paste to your cooler. Higher conductivity numbers indicate faster heat transfer. Premium pastes boast conductivity reaching 14 W/mK, while budget options are as low as 2 W/mK.

Thicker pastes won’t pump out or dry prematurely. High-density pastes also leave fewer voids between hardware. But density comes at the price of spreadability – too thick and application gets tricky. Low/medium viscosity offers a good balance.

For safe electrical insulation, verify the paste has high resistivity. Alternately, choose non-conductive ceramic pastes. Metallic/carbon options conduct electricity fine.

With the importance of proper thermal paste application made clear, another key consideration is paste brand. Avoid no-name cheap pastes of dubious composition and quality. Only purchase well-known brand name thermal compounds, such as:

Arctic Silver – The world’s premiere name in thermal paste since 1999. Their exceptional longevity and thermal conductivity makes their products the gold standard that all others are judged by.

Noctua – Creator of premium quiet cooling fans, their NT-H1 and NT-H2 pastes compliment their fans perfectly with excellent spreadability, stability and low curing times.

Thermal Grizzly – Used by top overclocking teams worldwide, Grizzly’s Kryonaut paste holds multiple extreme OC world records for performance. Fantastic, albeit costly, products.

Cooler Master – Known for their superb computer cases and CPU coolers, their MasterGel paste utilizes nano-diamond particles for class-leading thermal transfer without high cost.

Stick with one of the big, established thermal paste brands favored by enthusiasts and avoid random no-name paste of questionable quality – the reliability of every computer repair job depends on it!

With an understanding of what makes an effective thermal interface material, let us recommend 5 top-rated thermal pastes perfect for PC builds and repairs.

Photo via arcticsilver

Conductivity: 8.7 W/mK

Tested and trusted – AS5 offers exceptional stability and conductivity for the price. Sets the benchmark for premium thermal paste.

Photo via thermal-grizzly.

Conductivity: 12.5 W/mK

Top-tier performance for overclocking, with a well-earned reputation in enthusiast circles. Pricey but effective.

Photo via Noctua

Conductivity: 2.4 W/mK

A budget-friendly option perfect for typical users. Super easy to apply while still outclassing cheap pastes.

Photo via Cooler Master

Conductivity: 11 W/mK

Nano-diamond particles deliver extremely high conductivity. Unique consistency prevents pump out.

Photo via arctic

Conductivity: 8.5 W/mK

Strikes an ideal balance – very thermally conductive yet still reasonably priced. Great value choice.

Follow these best practices when replacing thermal paste on processors, GPUs, chipsets and RAM:

Use 91%+ isopropyl alcohol and coffee filters to fully clean all old paste until the hardware contacts are shiny and free of residue. Avoid corrosion by not using water or acidic cleaners.

You only need enough paste to fill microscopic valleys – a tiny rice grain sized dot of quality paste easily spreads to cover full dies. Avoid air bubbles by slowly spreading evenly across surfaces.

Putting paste solely on the CPU or GPU die leads to poor contact on the edges. Instead, thinly apply to BOTH the processor die and underside of the cooler for guaranteed heat transfer.

Clamp pressure is essential to ensure the paste makes tight contact in the microscopic gaps. Failure to firmly remount coolers is a common mistake made by amateur repair techs lacking experience.

Give freshly applied thermal paste at least 8 hours of heat cycling while avoiding any movement/vibrations. The compounds settle into an optimal thermally conductive bond during this curing time.

Follow those guidelines and your clients will enjoy reliable, high-performance computers thanks to properly controlled temperatures. Neglecting thermal paste and other cooling elements during computer repair work will lead to unhappy customers and damage your brand reputation!

While the above guidelines work for nearly all standard computer builds, extreme overclocking and cooling call for more intricate thermal paste application techniques:

Special liquid metal pastes like Coollaboratory Liquid Ultra feature superior heat transfer than traditional pastes, but electrically conductive requiring insulation.

Removing the CPU heat spreader allows mounting coolers/blocks directly to the silicon for max heat transfer, demanding perfectly smooth paste coats.

Unconventional approaches like spreading methods, imprinting, graphite pads, even no paste at all (relying solely on pressure) help optimize contact in custom setups.

However, extreme cooling modifications require extensive expertise – stick to traditional application as outlined above unless very experienced with computer repair and overclocking.

To demonstrate just how important proper thermal paste application is when doing computer repair jobs, here are examples from our computer shop highlighting drastic fixes purely from replacing old paste:

A custom gaming PC suffered random crashes and texture glitches in graphics-intensive games. We discovered the thermal paste on the Nvidia GTX 1080 graphics card was 5 years old, rock hard and ineffective. Replacing the ancient paste with fresh high-performance Grizzly Kryonaut paste solved the crashes completely. Frame rates soared and the system ran reliably even in long gaming sessions.

A contractor’s Dell laptop would randomly shut off under load with warning messages about high CPU temperatures. Opening the system revealed the CPU cooler had shifted, creating poor contact with the dried, cracked paste present. A fresh paste application allowed full heat transfer, cutting core temps by 15°C. The performance throttling and unexpected shutdowns disappeared.

An older office PC was bluescreening regularly with CPU overheating warnings despite an undemanding normal workload. Taking off the stock air cooler exposed a thick wall of compacted dust blocking airflow combined with paste that had turned to concrete. A deep clean and new thermal material moderated temperatures again for a rock-solid system.

In every case, replacing degraded or incorrectly applied thermal paste yielded drastic reliability improvements and temperature reductions. Do not skip paste reapplication during computer repairs!

While CPUs tend to receive all the attention, graphics processors (GPUs) require just as much care when it comes to thermal paste application during computer repairs. Modern GPUs sport massive die sizes and prodigious heat output that demands proper paste installation.

With graphics cards, pay special attention to thoroughly cleaning factory paste off RAM chips, power delivery phases and inductors too – not just the main GPU die itself. These ancillary components also benefit from fresh thermal paste and pads during repair. Failing to replace their paste invites artefacts, game crashes and burnt PCie power connectors.

For Nvidia RTX 3000 Founders Edition cards, also replace any pads protecting capacitors near the GPU or they may electrically short against the heatsink. Check forums to findthickness recommendations. Treat GPUs to new paste just like CPUs!

Still have some lingering questions about working with thermal paste for computer repairs and maintenance? Check out answers to some frequently asked questions below:

A: We recommend replacing CPU & GPU thermal paste every 2-3 years in computers regularly used for gaming, overclocking or resource-intensive tasks. More casual usage may allow paste to last 3-5 years before renewal is advised.

A: Excessive amounts of paste pump out the sides when the cooler mounts, making a mess. It can short out the motherboard circuitry in severe cases, especially electrically conductive pastes. Plus you waste expensive paste for no added benefit.

A: Insufficient paste coverage on hot spots leaves tiny air gaps that insulate heat, rapidly degrading cooling performance. Localized hot spots may emerge that throttles hardware speed. Always spread evenly & thinly across the entire CPU/GPU die surface.

A: Avoid reusing paste exposed to air for prolonged periods – the humidity causes premature drying and composition changes compared to an unopened syringe. Purchase conservatively to minimize waste instead of reusing old paste.

A: Any operation requiring CPU, GPU or chipset cooler removal warrants new paste, including upgrades, cleaning, troubleshooting overheating issues or replacing failed fans. Refitting stock coolers reusable, but we recommend fresh paste.

A: Yes, liquid metal pastes like Coollaboratory Liquid Ultra are electrically conductive. Avoid paste contacting board circuitry or SMD parts. Insulate surrounding SMDs with lacquer. Scrub off stained copper traces immediately before corrosion occurs.

A: Absolutely! Too little pressure leaves microscopic air gaps while excessive pressure squeezes out all paste. Tighten cooler mounts until firmly secured without over-twisting. Consult specifications for your cooler’s recommended mounting approach and torque.

A: Monitor CPU, GPU and hardware temperatures using free utilities like CoreTemp and GPU-Z. Thermal throttling and abrupt shutdowns at high but normal operating temperatures points to insufficient heat transfer from bad paste applications.

Follow those tips and thermal paste won’t give you any troubles during future computer upgrades and repairs! Let us know if you have any other thermal compound questions

In closing, no matter which processor, graphics card, console or mobile device you are repairing, new high-performance thermal paste truly makes or breaks the reliability of computers. Order top shelf paste in bulk to treat every computer repair job. Take the time to thoroughly clean off old dried paste and precisely apply the optimal small amount of fresh paste.

While the process takes patience and care, properly managing thermal paste will prevent future computer malfunctions. Your customers will thank you for the boosted speed, stability and extended lifespan from keeping temperatures low! Make thermal paste application your first priority with every repair job.

If your personal or business computer is experiencing random crashes, overheating shutdowns, throttling or other stability issues, the old ineffective thermal paste is likely the culprit.

Our expert technicians at Volta PC Upgrade & Repair offer reliable thermal paste replacement services and complete computer repairs tailored to your needs. We service desktops, laptops, graphics cards, and more with premium thermal compounds.

For affordable repairs carried out properly on the first attempt, contact Volta PC Upgrade & Repair today to request a competitive quote! Our convenient pickup, on-site or walk-in repair services backed by strong warranties give you peace of mind your system will run optimally for years to come.

Tai Seng Branch: 8 Burn Road #01-04, Trivex, Singapore 369977

Jurong Branch: Blk 132 #01-279C, Jurong Gateway Road, Singapore 6001324

The Acer Desktop boot loop issue can be a frustrating problem for users, causing their computers to restart continuously without reaching the operating system. This

When repairing a computer, whether it is a desktop PC, laptop, games console or mobile device, applying new thermal paste is by far the most

Hello there, fellow tech enthusiasts and PC users in Singapore! Have you ever faced the dreaded screen freeze or unexpected system crash? Often, these nuisances

|

*We are OPEN on 3 May 2025 (Polling Day). CLOSED ON 1 May 2025 (Labour Day) |